Aerocoreparts

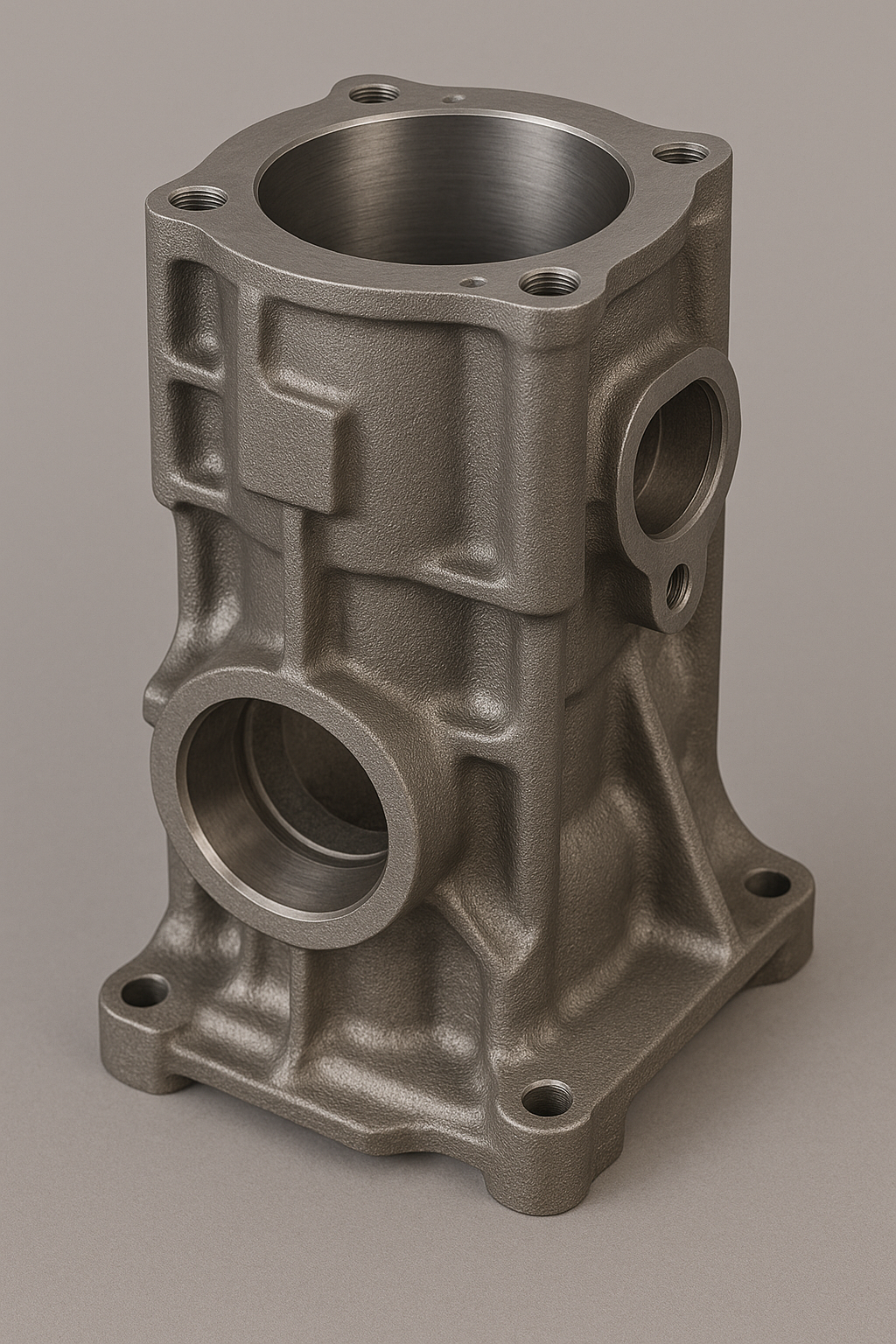

Aero Engine Cylinder Block

Aero Engine Cylinder Block

Couldn't load pickup availability

If the purchase amount exceeds USD 1,000, we recommend not using PayPal. Please contact us to arrange payment via a company-to-company bank account.

Sample Information

- Sample Material: GH4169

- Overall Dimensions: Length 1150 mm × Width 850 mm × Height 750 mm

📢 Important Notice

✓ This product is only available for production upon customer-supplied drawings or physical samples, and First Article Inspection (FAI) is required for confirmation.

✓ Sample production lead time: 5–7 working days

✓ Estimated shipping time: 3–7 days via air freight

✓ Delivery contents include: Finished parts, FAIR (First Article Inspection Report), Raw Material Certificates, Production Records, Inspection Records, Test Certificates, Shipping Documents, and complimentary items (if applicable)

🏗️ Technical Features

- High-Strength Materials: Manufactured from aerospace-grade aluminum alloys, titanium alloys, or high-temperature nickel-based superalloys, ensuring excellent mechanical strength and corrosion resistance under high temperature and pressure conditions.

- Precision Machining Process: Utilizing CNC machining, electrical discharge machining (EDM), high-pressure cooling, and surface strengthening treatments to achieve micron-level dimensional accuracy, meeting stringent engine reliability requirements.

- Lightweight Design: Combining structural optimization with advanced material selection to reduce overall engine weight and improve fuel efficiency.

- High-Temperature Resistance: Advanced heat treatment and coating technologies enhance cylinder block stability and service life in extreme high-temperature environments.

- Complex Structure Manufacturing Capability: Supports manufacturing of multi-chamber, multi-channel cooling designs and other complex internal geometries required by modern aero engines.

🚀 Application Fields

- Main cylinder block manufacturing and maintenance for civil aero engines

- Cylinder blocks for general aviation piston engines

- Structural components for commercial aircraft turbine engines

- Core components of turboshaft and turboprop engines

- Supporting parts for aero engine testing and inspection equipment

🌍 Usage Cases

- Boeing 737 Series Engines: Providing high-precision cylinder blocks for CFM56 turbofan engines, ensuring efficient operation and safety.

- Airbus A320 Series: Utilizing high-performance titanium alloy cylinder blocks to achieve lightweight, high-temperature, and corrosion resistance.

- General Aviation Piston Engines: Manufacturing various cylinder block parts for Lycoming and Continental engines, ensuring long-term reliability for small aircraft.

- International Civil Aircraft Maintenance Bases: Extending engine life and reducing maintenance costs through cylinder block inspection and remanufacturing.

- Aero Engine R&D Institutions: Supporting new engine cylinder block designs and rapid prototype manufacturing to accelerate development cycles.

🛡️ Quality Control Process ( NADCAP / AS9100 / ISO 9001 Compliance)

1️⃣ Raw Material Control

🔍 Key Control Points (KCP): Material Traceability / Certificate of Conformance

- All stainless steel, titanium alloys, and superalloys are procured from ASL-listed (Approved Supplier List) sources.

- Each batch must be accompanied by a Mill Test Report (MTR) with full heat number traceability.

- Critical materials comply with AMS standards, such as:

Inconel 718 – AMS 5662

Ti-6Al-4V – AMS 4928 - Incoming inspections include chemical and mechanical property re-verification through sample testing.(if applicable)

2️⃣ Process Control

🔍 KCP: Process Validation / Work Instruction / Special Process Control

- All operations follow validated Process Flow Charts (PFC) and documented Work Instructions (WI).

- Toolpaths are simulated using CAM software (e.g., Mastercam, NX) before execution.

- Special processes (welding, heat treatment, coating) are performed by NADCAP-accredited partners, and each process has a qualification record.

3️⃣ First Article & In-Process Inspection

🔍 KCP: FAI per AS9102 / In-Process Control Plan

- First Article Inspection is conducted in accordance with AS9102 Rev. B, covering all drawing dimensions and specifications.

- In-process checks include SPC (Statistical Process Control) for CTQ (Critical to Quality) features.

- All measuring instruments (e.g., calipers, CMMs, microscopes) are calibrated, have unique IDs, and are traceable to national standards.

4️⃣ Functional & Performance Testing

🔍 KCP: Test Plan / Functional Qualification / Acceptance Criteria

- If applicable, leakage, stiffness, and fitment tests are performed to validate performance.

- Every production batch is verified against design specification using predefined test methods.

- A formal Test Record is issued per part, clearly showing conformance with acceptance criteria.

5️⃣ Special Process Management (If Applicable)

🔍 KCP: NADCAP Accreditation / Process Certification

- All special processes (welding, thermal coating, etc.) are performed by NADCAP-certified suppliers.

- Each step is supported by a Process Approval Record, and only qualified, certified operators are assigned.

6️⃣ Final Inspection

🔍 KCP: Dimensional Inspection / Surface Quality / Conformance Documentation

- A complete dimensional inspection is conducted using CMMs.

- Surface roughness is checked to ensure Ra ≤ 0.8 μm; visual and optical inspection is performed on welds and critical surfaces.

- Certificate of Conformance (COC) and Final Inspection Checklist are completed prior to delivery.

7️⃣ Documentation & Traceability

🔍 KCP: Document Control / Lot Traceability / Data Retention

- Each cylinder block is traceable by a unique serial number, and accompanied by Process Router, QC Reports, Test Records, and Material Certificates.

- All quality records are retained for a minimum of 10 years, as required by AS9100 Clause 7.5.

- Upon request, a full Quality Assurance Package (QAP) is provided, including FAI, SPC charts, and test data.

Compliance Summary

| Standard / System | Key Requirements Addressed | Compliance |

|---|---|---|

| ISO 9001:2015 | Quality planning, continuous improvement, documentation | ✅ Fully compliant |

| AS9100D | Aerospace quality management, FAI, risk-based thinking, traceability | ✅ Fully compliant |

| NADCAP (if applicable) | Special process control (e.g., heat treat, coating, welding) | ✅ Via certified subcontractors |

| Customer Audit Checklists | Support full gap analysis, documentation mapping, and pre-audit responses | ✅ Supported |

We can prepare complete product documentation and quality-related files in accordance with specific customer requirements.

Sample, No Commercial Value, Not for Resale.

Send us your drawings or sample information via email, and we will reply within 24 hours! Sales@aerocoreparts.com

Share