Aerocoreparts

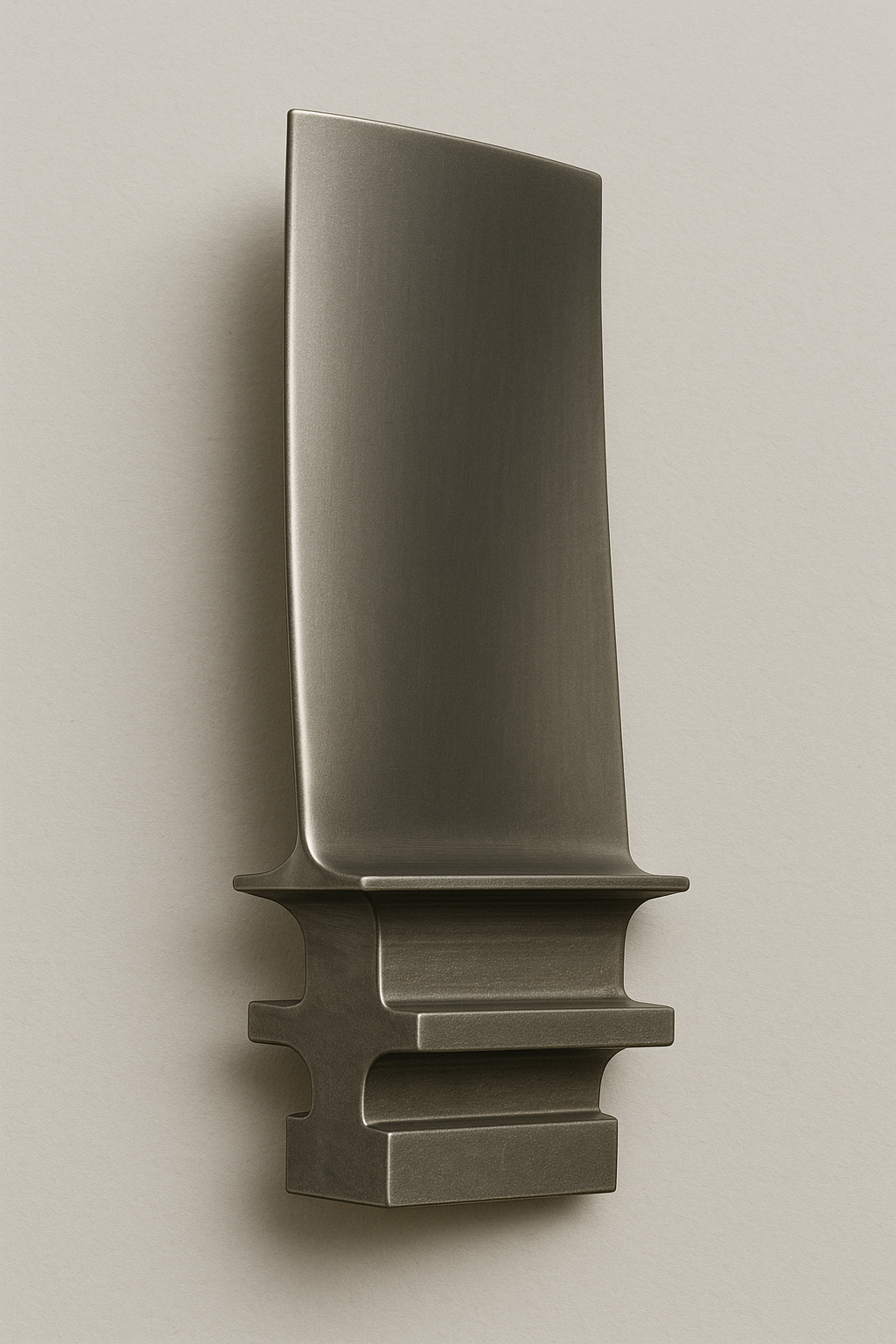

Aerospace Engine Integrally Bladed Rotor (IBR)

Aerospace Engine Integrally Bladed Rotor (IBR)

Couldn't load pickup availability

If the purchase amount exceeds USD 1,000, we recommend not using PayPal. Please contact us to arrange payment via a company-to-company bank account.

Our aerospace engine Integrally Bladed Rotor (IBR) is a precision-machined component crafted from high-quality titanium alloy Ti-6Al-4V and nickel-based superalloys. This IBR is designed for optimal performance in aerospace engines including GE F110, F119, and Trent 1000.

📢 Important Notice

✓ This product is only available for production upon customer-supplied drawings or physical samples, and First Article Inspection (FAI) is required for confirmation.

✓ Sample production lead time: 5–7 working days

✓ Estimated shipping time: 3–7 days via air freight

✓ Delivery contents include: Finished parts, FAIR (First Article Inspection Report), Raw Material Certificates, Production Records, Inspection Records, Test Certificates, Shipping Documents, and complimentary items (if applicable)

🏗️ Technical Features:

| Item | Description |

|---|---|

| Material | Titanium alloy (Ti-6Al-4V) or superalloy (nickel-based alloy) |

| Manufacturing | 5-axis CNC milling, EDM, precision casting or additive manufacturing (EBM) |

| Advantages |

|

🚀 Application Areas:

- Aerospace engine compressors

- Turbofan engine front fan stages

- High-end gas turbines (industrial power generation)

🌍 Notable Use Cases:

| Model | IBR Stage | Manufacturer |

|---|---|---|

| GE F110 | High-pressure compressor section | GE Aviation |

| Pratt & Whitney F119 | Full compressor | Pratt & Whitney |

| Rolls-Royce Trent 1000 | Low-pressure compressor | Rolls-Royce |

IBR is a key technology for achieving lightweight and high reliability in modern high-performance aerospace engines. We can provide custom quotes based on specific requirements.

🛡️ Quality Control Process ( NADCAP / AS9100 / ISO 9001 Compliance)

1️⃣ Raw Material Control

🔍 Key Control Points (KCP): Material Traceability / Certificate of Conformance

- All materials (e.g., Ti-6Al-4V, Inconel 718) are sourced from pre-approved suppliers listed on the ASL.

- Each batch includes a Mill Test Report (MTR) with heat number traceability.

- Materials must conform to aerospace-grade specifications (e.g., AMS 4928 / AMS 5662).

- Incoming inspection includes verification of chemical composition and mechanical properties.(if applicable)

2️⃣ Process Control

KCP: Process Validation / Work Instruction / Special Process Control

- Manufacturing follows validated Process Flow Charts and Work Instructions.

- CAM toolpaths are verified in simulation (Mastercam, NX) before execution.

- Welding, heat treatment, and coatings are performed by NADCAP-certified vendors with process qualification.

3️⃣ First Article & In-Process Inspection

KCP: FAI per AS9102 / In-Process Control Plan

- FAI is conducted per AS9102 Rev. B to ensure full design compliance.

- SPC applied on Critical-To-Quality (CTQ) features during processing.

- All gauges and CMMs are calibrated and traceable to national standards.

4️⃣ Functional & Performance Testing

KCP: Test Plan / Functional Qualification / Acceptance Criteria

- If applicable (e.g., in rotating assembly), rotor balancing and vibration testing are conducted.

- Mechanical integrity (tensile, fatigue) tested on coupons.

- Each rotor undergoes inspection for airfoil geometry and profile accuracy.

5️⃣ Special Process Management (If Applicable)

KCP: NADCAP Accreditation / Process Certification

- Special processes (e.g., e-beam welding, thermal barrier coatings) executed by NADCAP-certified providers.

- Each process step has a Process Approval Record and qualified operator ID.

6️⃣ Final Inspection

KCP: Dimensional Inspection / Surface Quality / Conformance Documentation

- Full dimensional inspection via CMM against 3D CAD and drawings.

- Surface finish (e.g., Ra ≤ 0.8μm) and edge radii are verified.

- Final Certificate of Conformance (COC) issued upon completion.

7️⃣ Documentation & Traceability

KCP: Document Control / Lot Traceability / Data Retention

- Each IBR is traceable via a unique serial number.

- Documentation includes Process Router, QC Report, Test Results, MTRs.

- Records retained ≥10 years per AS9100 Clause 7.5.

Compliance Summary

| Standard / System | Key Requirements Addressed | Compliance |

|---|---|---|

| ISO 9001:2015 | Quality planning, continuous improvement, documentation | ✅ Fully compliant |

| AS9100D | Aerospace quality management, FAI, risk-based thinking, traceability | ✅ Fully compliant |

| NADCAP (if applicable) | Special process control (e.g., heat treat, coating, welding) | ✅ Via certified subcontractors |

| Customer Audit Checklists | Support full gap analysis, documentation mapping, and pre-audit responses | ✅ Supported |

We can prepare complete product documentation and quality-related files in accordance with specific customer requirements.

Sample, No Commercial Value, Not for Resale.

Send us your drawings or sample information via email, and we will reply within 24 hours! Sales@aerocoreparts.com

Share