Aerocoreparts

Aerospace-Grade Custom Sealing Component

Aerospace-Grade Custom Sealing Component

Couldn't load pickup availability

If the purchase amount exceeds USD 1,000, we recommend not using PayPal. Please contact us to arrange payment via a company-to-company bank account.

✈ Product Overview

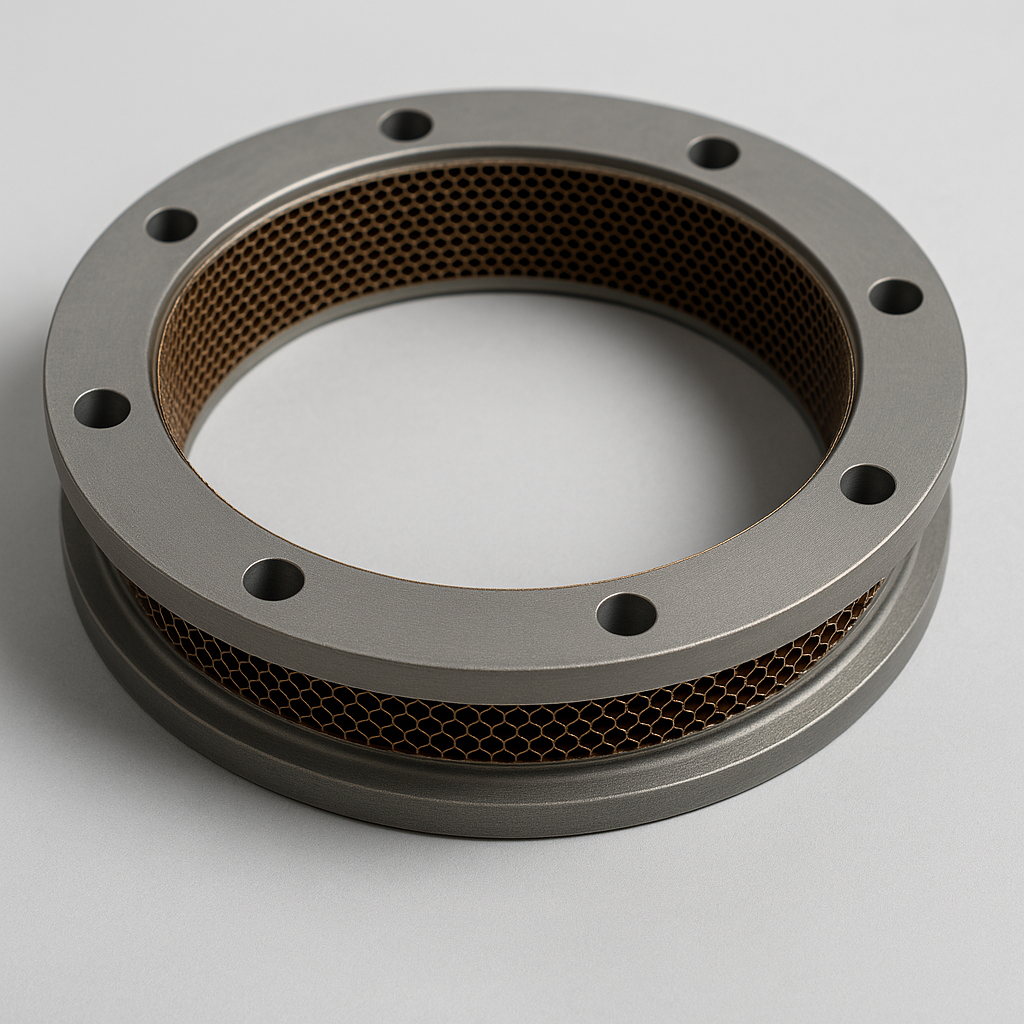

The honeycomb seal ring is a high-performance, non-contact sealing component widely applied in compressor and turbine stages of aircraft engines. Built from high-temperature resistant alloys and structured with precision-engineered honeycomb geometry, it minimizes gas leakage under extreme thermal and dynamic conditions. The result: improved thermal efficiency, reduced fuel consumption, and extended engine service life.

💡 Technical Features

| Feature | Description |

|---|---|

| High-Temperature Alloys | Materials such as Inconel 718 and 1Cr11Ni2MoV compliant with AMS 5662 / AMS 5917 |

| Engineered Honeycomb Structure | Cell size 0.8–1.2 mm, ensures controlled leakage with minimum mass |

| Laser Welded and Precision Fit | Honeycomb brazed or welded onto base ring with controlled tolerances |

| Ablative and Rub-Tolerant | Optional wear-resistant coatings (e.g., ceramic or MCrAlY) allow adaptive contact |

| Thermo-Mechanical Conformance | FEM-supported gap fit design considering in-service thermal expansion |

📐 Sample Reference

| Item | Specification |

|---|---|

| Material | 1Cr11Ni2MoV (High-temp corrosion-resistant SS) |

| Dimensions | Outer Diameter: Ø800 mm × Height: 240 mm |

| Customization Condition | Production based on customer drawings or physical samples (FAI required) |

🧩 Application Fields

- Sealing between compressor exit and turbine inlet

- Inter-stage seals in high- and low-pressure turbines

- Shaft sealing systems (axial or radial)

- Variable Inlet Guide Vane (VIGV) or Variable Stator Vane (VSV) sealing

- Engine overhaul, MRO, or performance upgrade replacements

🏗 Manufacturing & Delivery Highlights

| Item | Detail |

|---|---|

| First Article Lead Time | 7–14 working days |

| Shipping Method | 3–7 days via international air freight |

| Included Documentation | FAI Report, Material Certificates, Dimensional & Functional Inspection Records, Test Certificates, Shipping Documents, etc. |

📦 Included Quality Documentation

- ✅ First Article Inspection Report (FAIR) – AS9102 Rev.B compliant

- ✅ Mill Test Reports (MTRs) – Traceable to AMS material standards

- ✅ Process and Inspection Records – Full traceability from raw material to final shipment

- ✅ Performance Test Reports – As applicable to rotating components

- ✅ Certificate of Conformance (CoC)

🔍 Comprehensive Quality Control

| Process Stage | Key Control Points (KCPs) |

|---|---|

| Raw Material Control | ASL-sourced; full heat number traceability; incoming chemical & mechanical validation |

| Manufacturing Process Control | Based on validated Process Flow Charts (PFCs) and Work Instructions (WIs); critical processes subcontracted to NADCAP-certified providers |

| First Article & In-Process QC | AS9102 FAI; SPC on CTQ features; CMM-calibrated dimensional checks |

| Performance & Functional Tests | Includes rotor balancing, vibration, tensile strength, and fatigue testing where applicable |

| Special Process Oversight | EB welding, TBC coating, cladding performed by certified operators with documented approvals |

| Final Inspection | CMM with CAD-model comparison; surface finish ≤ Ra 0.8μm; edge radii validated |

| Documentation & Traceability | Unique serial ID per ring; records retained for a minimum of 10 years per AS9100 Clause 7.5 |

🌍 Reference Engine Applications

| Engine Platform | Application Role | Key Performance Contributions |

|---|---|---|

| CFM LEAP-1A/B | IGV area sealing | Improved surge margin and fuel burn efficiency |

| PW1100G-JM (GTF) | Adjustable vane seal ring | Low-speed airflow tuning and fan-compressor matching |

| GE Passport / GE9X | Pre-turbine gas path sealing | Extreme bypass ratio and thermal margin support |

| AECC Domestic Engines | VIGV sealing (localization focus) | Secure domestic supply and aerodynamic optimization |

📩 Next Steps

We offer engineering collaboration, rapid prototyping, and full documentation for pre-production evaluation.

If you have a design drawing or a physical sample, we will support you with:

- Custom quotation & technical specification (TDS & RFQ)

- CAD-based design review and production feasibility feedback

- FAI planning and pilot sample production

📋 Technical Data Sheet | Honeycomb Seal Ring

| Item | Details |

|---|---|

| 1. Product Name | Honeycomb Seal Ring |

| 2. Application | Aerospace Gas Turbine Engine (Compressor & Turbine Sections) |

| 3. Manufacturing Mode | Made-to-Drawing or Sample-Based Production |

| 4. Material Options | • 1Cr11Ni2MoV (Stainless Steel) • Inconel 718 / X750 (Nickel-based Superalloys) • Other aerospace-grade alloys per AMS standards |

| 5. Typical Dimensions (Customizable) | • Outer Diameter: Up to Ø800 mm • Height: Up to 240 mm |

| 6. Structural Design | • Honeycomb cell size: 0.8 – 1.2 mm • Brazed or welded to base ring • Surface finish: Ra ≤ 0.8 μm |

| 7. Surface Coatings (Optional) | • Ceramic coating • MCrAlY • Nitriding or laser cladding |

| 8. Applicable Standards | • AMS 5662 / AMS 5917 / AMS 4928 • AS9100 / NADCAP / ISO 9001 |

| 9. Lead Time | • Sample: 7–14 working days • Shipping: 3–7 days via air freight |

| 10. Quality Control Deliverables | • FAIR (AS9102 Rev.B) • Mill Test Report (MTR) • Dimensional Inspection Report • Functional Test Report (if applicable) • Certificate of Conformance (CoC) |

📝 Request for Quotation (RFQ)

Please provide the following for quotation:

- Technical drawing or physical sample (if available)

- Material specification (or preferred alloy)

- Quantity and batch size

- Coating or heat treatment requirements (if any)

- Certification needs (FAI, CoC, NADCAP, etc.)

- Target lead time and shipping terms

Sample, No Commercial Value, Not for Resale.

Send us your drawings or sample information via email, and we will reply within 24 hours! Sales@aerocoreparts.com

Share