Aerocoreparts

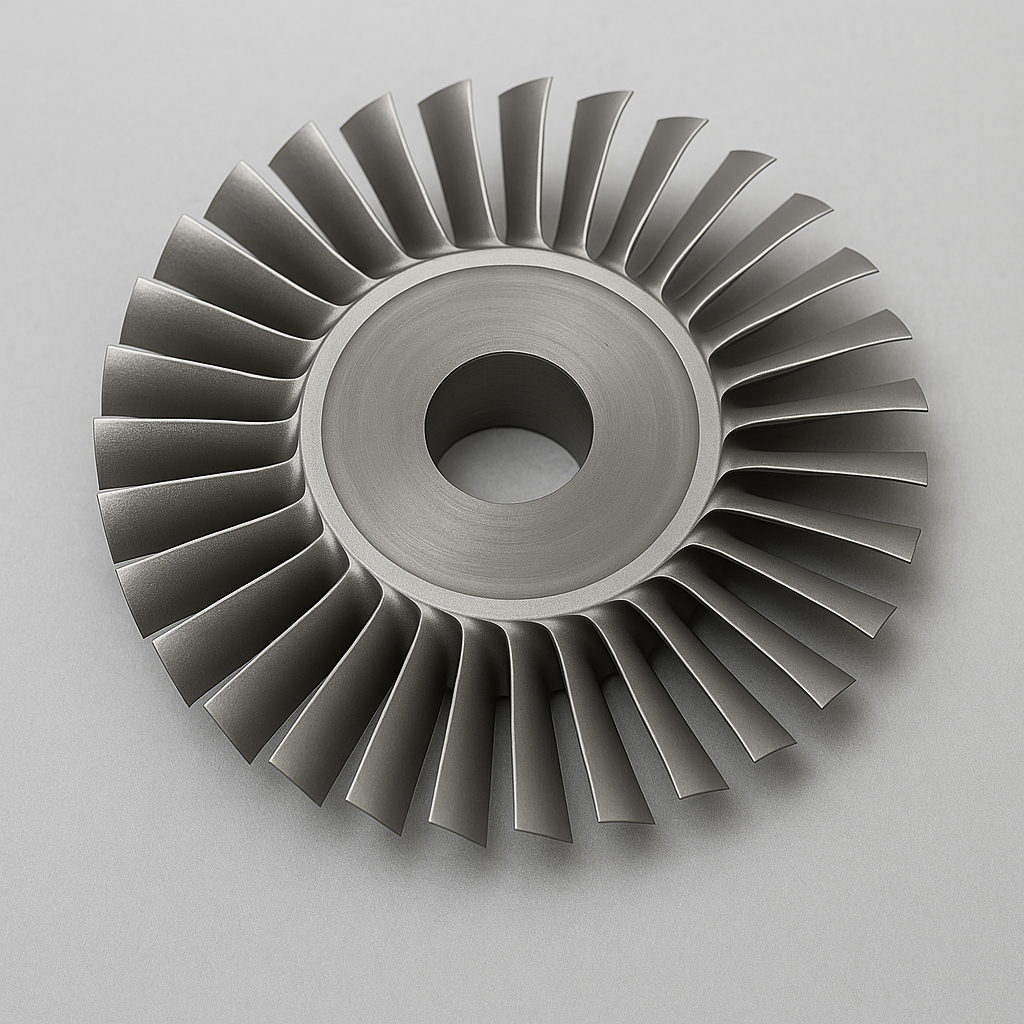

Industrial Turbine Impeller/Blade Disk

Industrial Turbine Impeller/Blade Disk

Couldn't load pickup availability

If the purchase amount exceeds USD 1,000, we recommend not using PayPal. Please contact us to arrange payment via a company-to-company bank account.

We specialize in the manufacturing of industrial turbine impellers and blade disks used in gas turbines, steam turbines, and centrifugal compressors. With over 10 years of experience in 5-axis CNC machining, we deliver fully customized, high-precision rotor components for aerospace, energy, and power generation applications. Our impellers and blade disks are manufactured from aerospace-grade materials—including Inconel 718, Ti-6Al-4V, and 17-4PH stainless steel—and are subjected to rigorous quality control processes in compliance with AS9100, NADCAP, and ISO 9001 standards.

📢 Important Notice

✓ This product is only available for production upon customer-supplied drawings or physical samples, and First Article Inspection (FAI) is required for confirmation.

✓ Sample production lead time: 5–7 working days

✓ Estimated shipping time: 3–7 days via air freight

✓ Delivery contents include: Finished parts, FAIR (First Article Inspection Report), Raw Material Certificates, Production Records, Inspection Records, Test Certificates, Shipping Documents, and complimentary items (if applicable)

🏗️ Technical Features

- High-Temperature Strength Alloys: Manufactured from nickel-based or titanium-based superalloys to ensure structural integrity and durability under high-temperature and high-speed conditions.

- Precision Forging and Heat Treatment: Advanced forging combined with uniform heat treatment delivers superior density and mechanical properties, minimizing fatigue cracks and stress concentrations.

- Complex Geometry Design: Optimized aerodynamic blade profiles and disk structures using 3D CAD/CAE modeling for a perfect balance between lightweight construction and operational efficiency.

- Surface Enhancement Treatments: Laser cladding, nitriding, or ceramic coatings available to improve corrosion and wear resistance, extending operational lifespan.

- Integrated Multistage Disk Manufacturing: Supports multi-stage blade integration to enhance overall engine power transmission efficiency and stability.

🚀 Application Fields

- Manufacturing of compressor and turbine disks for civil aviation gas turbines

- Core components for general aviation and commercial aircraft engines

- R&D and mass production of next-generation high-performance aero engines

- Engine maintenance, overhaul, and performance upgrade services

- Precision components for engine performance testing and verification systems

🌍 Application Cases

- CFM LEAP Engines: Provides critical materials and manufacturing processes for high-pressure turbine disks, achieving weight reduction and thermal durability.

- Pratt & Whitney PW1000G Series: Disk materials and machining ensure stable performance at high rotational speeds.

- Domestic Aeroengine Manufacturers: Localized disk design and production solutions enable import substitution and supply chain security.

- Global MRO Centers: Disk repair and performance enhancement services extend engine lifespan and reduce operating costs.

- Aerospace Research Institutions: Rapid prototyping and testing of new disk profiles to support advanced technology validation and promotion.

🛡️ Quality Control Process

Compliant with NADCAP / AS9100 / ISO 9001

1️⃣ Raw Material Control

Key Control Points (KCP): Material Traceability / Certificate of Conformance

- All materials (e.g., Ti-6Al-4V, Inconel 718) are sourced from pre-approved suppliers listed in the ASL (Approved Supplier List).

- Each batch is accompanied by a Mill Test Report (MTR) with full heat number traceability.

- Materials conform to aerospace standards such as AMS 4928 / AMS 5662.

- Incoming inspection includes chemical and mechanical property verification (where applicable).

2️⃣ Process Control

KCP: Process Validation / Work Instructions / Special Process Oversight

- All manufacturing steps follow validated Process Flow Charts (PFC) and detailed Work Instructions (WI).

- CAM toolpaths are verified through simulation software (Mastercam, NX) prior to execution.

- Welding, heat treatment, and surface coating are executed by NADCAP-accredited subcontractors with documented qualifications.

3️⃣ First Article & In-Process Inspection

KCP: AS9102 FAI / In-Process Control Plan

- FAI is conducted in accordance with AS9102 Rev. B to ensure full compliance with design specifications.

- Statistical Process Control (SPC) is applied to Critical-to-Quality (CTQ) features during production.

- All gauges and Coordinate Measuring Machines (CMMs) are calibrated and traceable to national standards.

4️⃣ Functional & Performance Testing

KCP: Test Plan / Functional Qualification / Acceptance Criteria

- Where applicable (e.g., for rotating components), rotor dynamic balancing and vibration testing are performed.

- Mechanical integrity tests such as tensile and fatigue testing are performed on sample coupons.

- Each rotor is inspected for airfoil geometry and profile accuracy.

5️⃣ Special Process Management (if applicable)

KCP: NADCAP Accreditation / Process Certification

- Special processes (e.g., electron beam welding, thermal barrier coatings) are executed by NADCAP-certified partners.

- Each process step is supported by Process Approval Records and operator qualifications.

6️⃣ Final Inspection

KCP: Dimensional Check / Surface Quality / Conformance Documentation

- Full dimensional inspection conducted using CMM based on 3D CAD models and drawings.

- Surface finish (Ra ≤ 0.8μm) and edge radii are verified.

- Certificate of Conformance (COC) is issued upon successful final inspection.

7️⃣ Documentation & Traceability

KCP: Document Control / Lot Traceability / Record Retention

- Each IBR is fully traceable via a unique serial number.

- Documentation package includes Process Routers, QC Reports, Test Results, and MTRs.

- All records are retained for a minimum of 10 years in compliance with AS9100 Clause 7.5.

Compliance Summary

| Standard / System | Key Requirements Met | Status |

|---|---|---|

| ISO 9001:2015 | Quality planning, continuous improvement, documentation | ✅ Fully Compliant |

| AS9100D | Aerospace QMS, FAI, risk-based thinking, traceability | ✅ Fully Compliant |

| NADCAP (if applicable) | Special process control (e.g., heat treat, coating, welding) | ✅ Via Certified Partners |

| Customer Audit Checklist | Full support for gap analysis, documentation mapping, and audit readiness | ✅ Supported |

We can prepare complete product documentation and quality-related files in accordance with specific customer requirements.

Sample, No Commercial Value, Not for Resale.

Send us your drawings or sample information via email, and we will reply within 24 hours! Sales@aerocoreparts.com

FAQ

Q1: What is the typical lead time for industrial turbine impellers?

A1: Standard lead times range from 4 to 6 weeks for most configurations, depending on material and geometry complexity.

Q2: Can you handle high-temperature alloys like Inconel 718?

A2: Yes, we have extensive experience machining Inconel 718 and other superalloys with strict heat treatment and inspection procedures.

Q3: Do you provide dynamic balancing certification?

A3: Absolutely. Each rotor is dynamically balanced and certified to ISO 1940-1 standards (G2.5 level or better).

Share